Pipe Type: Seamless Tube, Seamless Steel Tube, Seamless Precision Tube

Application: For Mechnical Structures, Hydraulic Equipment, Automative Parts

Specification: OD: 4mm ~ 114mm

WT: 0.5mm ~ 8.0mm

LENGTH: Fixed Length(5.8/6/11.8/12mtr), SRL, DRL

Standard: DIN 2391, EN 10305, GB/T3639-2009

Ends: Square Ends/Plain Ends(straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Production Process of Precision Steel Tube

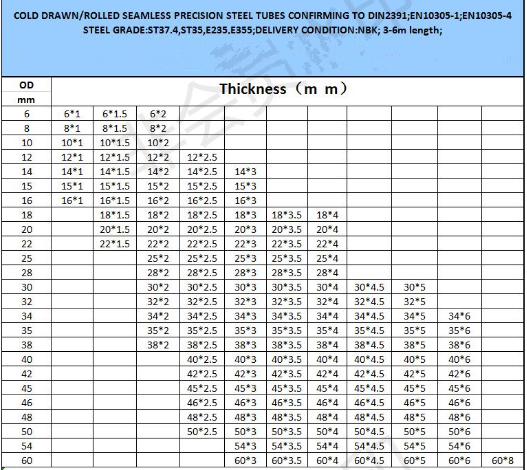

Specification of Precision Steel Tube

Technical Data of Precision Steel Tube

Steel Grade and Chemical Compositions

| SteelGrade | C | Si | Mn | P | S | |

| Steel Name | Steel Number | max | max | max | max | max |

| E155 | 1.0033 | 0.11 | 0.35 | 0.70 | 0.025 | 0.025 |

| E195 | 1.0034 | 0.15 | 0.35 | 0.70 | 0.025 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.20 | 0.025 | 0.025 |

| E275 | 1.0225 | 0.21 | 0.35 | 1.40 | 0.025 | 0.025 |

| E355 | 1.0580 | 0.22 | 0.35 | 1.60 | 0.025 | 0.025 |

Heat treatment method:

+Cc, +LCc, +SR,+Ad,+N

Note: Special steel grade is also available, according to customer request.

Please specify the steel grade and heat treatment mothod when sending the enquiry!

Product Advantages of Precision Steel Tube

We can produce all sizes of boiler tubes, according to European, Chinese, American, Japanese standard. With fast delivery time, supportive payment term.

All tubes production processes are controlled strictly, with high level of quality requirement, all tubes are inspection before delivery, and also accept third party inspection before delivery.