Pipe Type: SSAW Pipe, SSAW Steel Pipe, Spiral Steel Pipe, Welded Spiral Pipe, Double Submerged Arc Welded (DSAW) Steel Pipe

Application: Fluids Transmission Service, Ordinary Structural Support

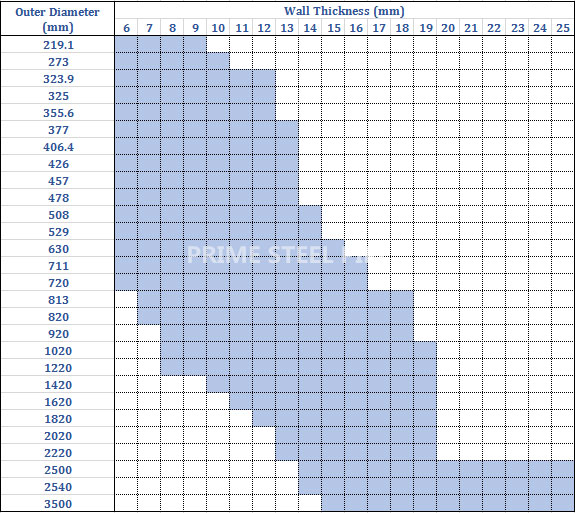

Specification: OD: 219.1mm ~ 3500mm

WT: 6mm ~ 25mm (Up to 1'')

LENGTH: 6mtr ~ 18mtr, SRL, DRL

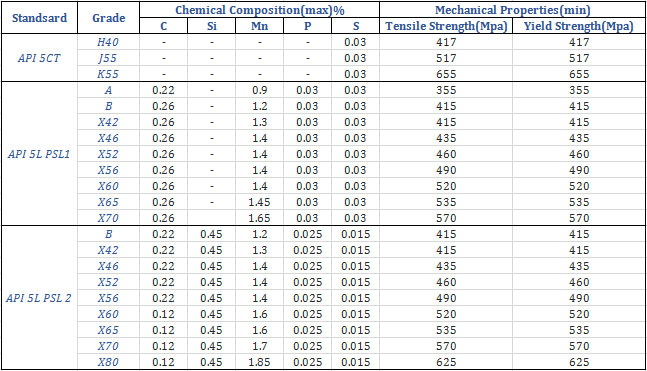

Standard & Grade: ASTM A53 Grade A/B/C, AWWA C200

End: Beveled Ends, Square Cut, With LTC/STC/BTC/VAM Connection

Surface: Bare, Lightly Oiling, Black Painting, Anti-corrosion Coating(FBE/2PE/3PE)

Packing: In Bulk, Ends Protector on Both Sides, Waterproof Materials Wrapped

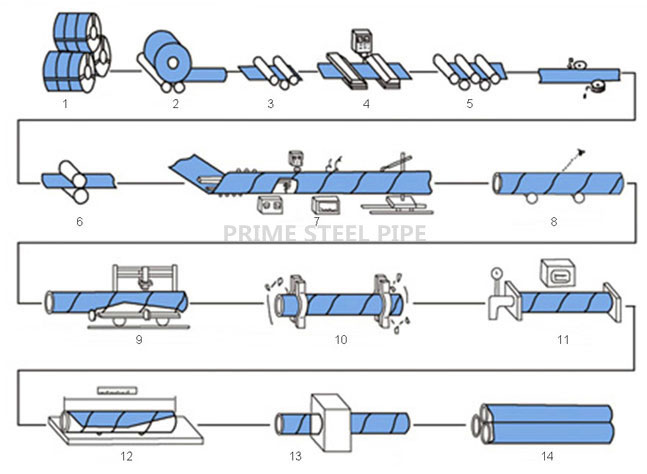

Production Process of SSAW Steel Pipe

1. Hot Rolled Coils Preparation & Inspection --- 2. Un-Coiling and Flattening --- 3. Leveling --- 4. Cutting --- 5. Centring & Sided Trimming & Edge Milling --- 6. Centring --- 7. Welding & Ultrasonic Inspection --- 8. Plasma Cutting --- 9. Slag Removing and X-ray Inspection --- 10. End Facing --- 11. Hydrostatic Testing --- 12. Final Visual Inspection (Tasting Lab) --- 13. Coating --- 14. Weighing and Stenciling and Storing

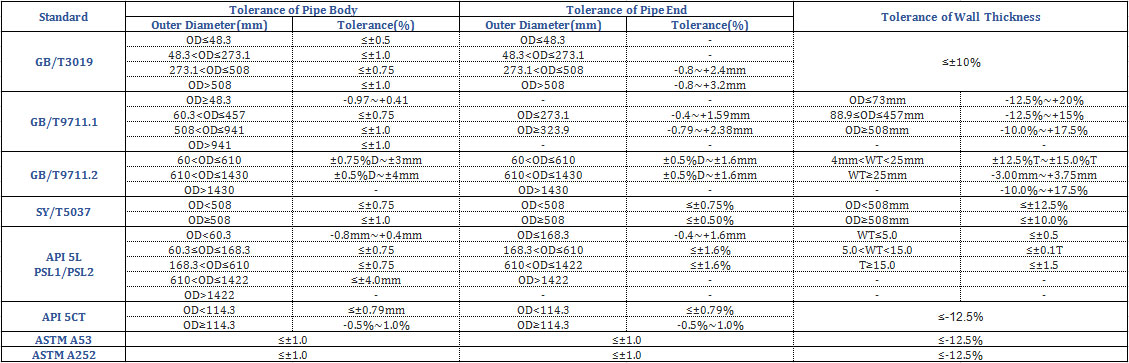

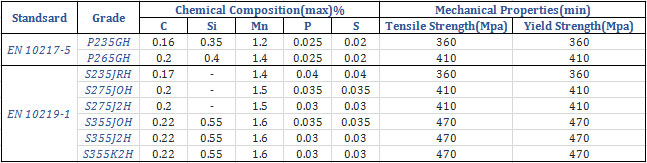

Specification of SSAW Steel Pipe

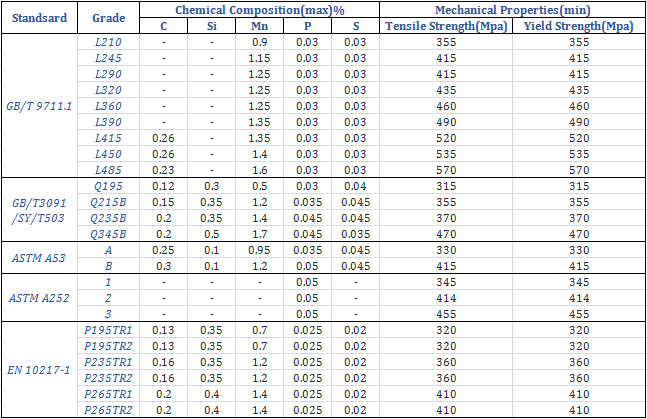

Technical Date of SSAW Steel Pipe

SSAW Steel Pipe Competitive Advantages

1.As long as the forming angle is changed,steel pipes of various calibers can be produced with strips of the same width,which is easy to adjust.

2.Because it is formed by continuous bending,the length of helical tube is not limited and can be determined at will.

3.The spiral shape of the weld is evenly distributed around the whole spiral pipe,so the spiral pipe has high dimensional accuracy and strength.

4.Easy to change size,suitable for small batch,multi-variety spiral tube production.

The weld length of spiral pipe is longer than that of straight pipe of the same specification.Under the same specification wall thickness,the pressure of spiral pipe is larger.